QLC™ HIGH-PERFORMANCE FRICTION REDUCING COATINGS

ULTIMATE PART PROTECTION & FRICTION REDUCTION

WHAT WE DO- We build or create a new surface on existing materials by enhancing the base material's properties. This is done by applying our unique rare earth materials using our proprietary Force Altered Technology. The result is a new extremely low-friction and durable surface of your part. This is truly "GAME CHANGING TECHNOLOGY" for a variety of industries from- Aviation, aerospace, automotive, industrial, Marine, and more. If there is sliding friction, then YES, your parts WILL benefit from our QLC™ Thin-film Quartz-Like-Ceramic coating.

QLC® vs. DLC

Experience the future of high-performance coatings with Quartz-like Ceramic QLC™—a breakthrough material engineered for the most demanding environments, from race engines and aerospace systems to advanced weapons platforms.

QLC™ offers a dramatically lower coefficient of friction than traditional Diamond-like Carbon DLC, reducing drag, minimizing heat generation, and extending the lifespan of precision components. But QLC™ doesn’t just resist heat—it actively helps manage it. Its unique molecular structure allows it to transfer heat away from critical parts, protecting components from thermal stress and improving overall system stability and reliability.

Unlike DLC coatings, which are prone to cracking, delaminating, or ablating under mechanical extremes and causing catastrophic engine failure, QLC™ bonds cleanly and securely to surfaces. It won’t degrade, delaminate, or contaminate surrounding systems, ensuring continuous operation without risk to critical precision components.

QLC™ is also ultra-thin and precision-applied, preserving exact tolerances and eliminating the need for part redesigns or compromises in fit.

In industries where failure isn't an option, QLC™ stands alone. With its superior friction profile, unmatched durability, and advanced heat dissipation, QLC™doesn’t just protect your systems—it elevates them. Choose QLC™ for more reliable performance, cooler operating temperatures, and prolonged part life—for no-compromise performance.

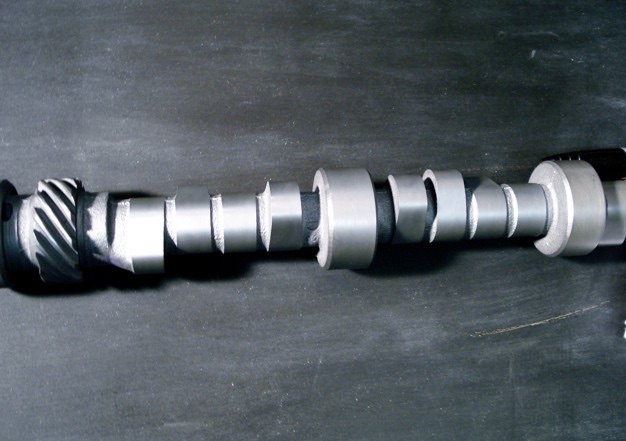

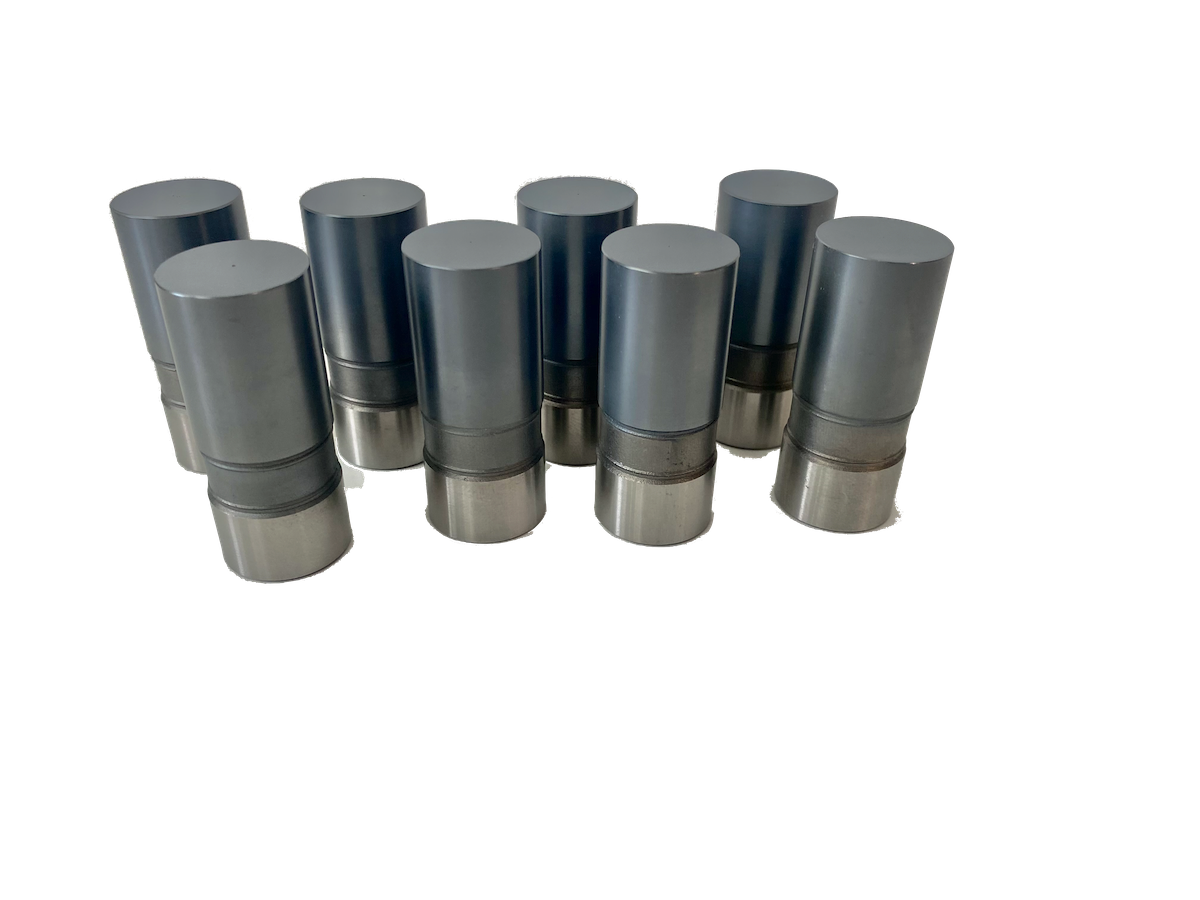

WHAT THIS MEANS FOR YOU- All forms of racing have restrictive rules— but, where rules dictate what cam must be used and/or flat tappet lifters only, this means what we do can give you the competitive advantge you need to hoist the trophy and add that much-needed cash back to your racing operation.

In the highly competitive classes in NHRA, like Stock Eliminator and nearly every circle track category like- Street Stock, Late Models, Pure Stocks, and even the mini-sprint and other motorcycle engine classes, rules limit modifications and specs for nearly every component of these engines.

Rocketman RACE coatings will do these important things for you:

-Your parts will last much longer due to the reduced friction and heat they experience as a result of using of our coatings because

AND- our coating IS A LUBRICANT ITSELF!

-Perhaps more importantly- by coating your parts with one of our specially designed coatings, you will FREE UP TRAPPED HORSEPOWER by reducing power-robbing friction wherever you use our coatings.

We can’t guarantee you’ll win more races, but our coatings will absolutely play a critical role in the power and longevity of your engine and transmission.

OUR PROCESSES AND MATERIALS- are cutting-edge. We embed our unique rare earth materials called QLC™ into the surface of your part by exerting a pressure of many, many atmospheres, literally FORCING our materials into the surface. This process ALTERS the chemical composition of the outer layer of the part creating a new low friction surface. In other words not actually a coating but a new Force Altered surface.

This process enhances both the sliding and rolling performance with significant friction reduction.

An added benefit of the new surface is that it is now oleophilic ie: has the ability to hold oil unlike other "coatings", like DLC. Even at start-up, your parts are immune to the a lack of oil since our coating IS A LUBRICANT ITSELF!

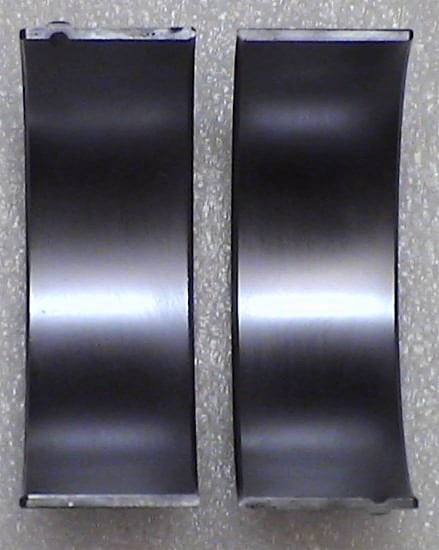

Featured Pictures

Some examples of our reccent work

Get in Touch

Please drop us an email if you prefer and we'll get back to you as soon as we can. Thank you again for visiting our site.